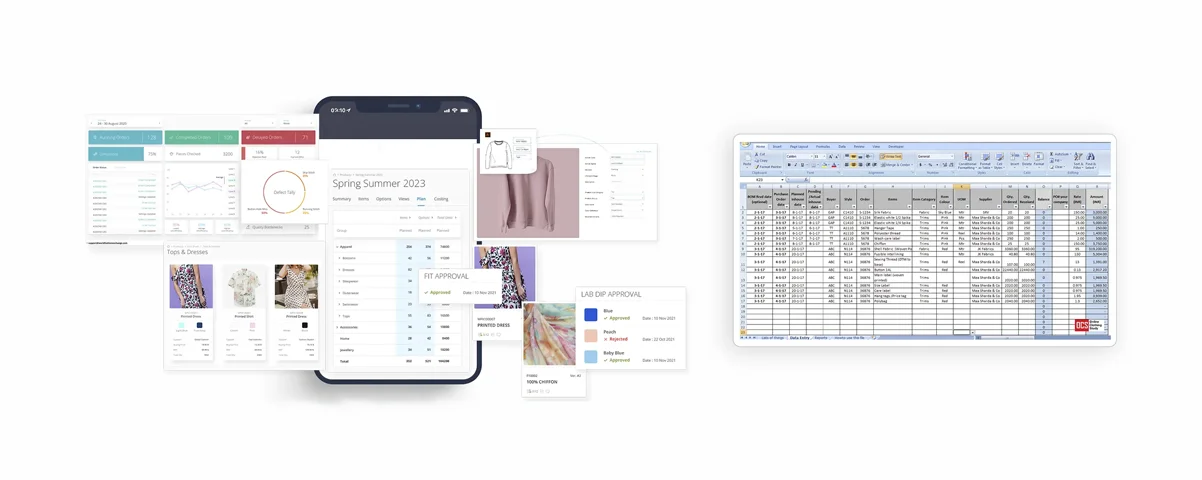

Advantages of creating a Tech Pack in PLM VS excel sheet

Introduction

If you’ve ever dreamed of starting your own fashion line, you would have heard about the dreaded fashion ‘Tech Pack.’ The tech pack often sounds like a scary task that will just add to your already-overflowing list of to-dos, but it’s actually one of the most important things you’ll do when developing your products.

Everyone in the fashion industry—whether you’re a designer, buyer, merchandiser, or manufacturer—understands the importance of a detailed Tech Pack (short for Technical Package). It is one of the most important documents in the apparel industry as it helps a designer communicate all the necessary details about styling options and specifications for development of a garment to their manufacturer or product developer.

A tech pack should include as much information as possible while making all your expectations clear. Inaccurate or inadequate tech packs can result in wasted time and resources caused by delays in communication or misinterpretation among manufacturers and Quality Assurance teams.

What should go into creating a good tech pack?

A tech pack needs to include all the technical information about a product. This includes technical drawings and illustrations, description, measurement charts, bill of materials, colorways, label information, product category and so on, depending on how detailed you want to get. It is generally created with the assistance of fashion designers, pattern makers, merchandisers and other people in the product development team.

The problem with using Excel/PDF tech packs

Traditionally, fashion companies tend to opt for an excel spreadsheet to create their tech pack. It’s tempting to open a spreadsheet or doc to put one together – it’s affordable and seems easy enough on the surface. But the moment you begin working on a complex product, it can get tedious to try and fit all of that information into one file. This is because a doc or a spreadsheet is just not built for the type of information being captured.

With an excel sheet, you have to organize all the data into columns and rows. A lot of time goes into finding out how to line up all the columns and rows correctly to get this right. If there is any change, then you will have to go through and make adjustments all over again. Additionally, once you’ve sent the file to your manufacturers, you have to send new versions every time there is a change. As you add more products, this process can become a nightmare.

At its core, Excel is a great spreadsheet software that allows you to create tables, graphs, and calculations using formulas. Excel has its advantages for many tasks but it’s just not the software tool for apparel tech packs.

Check out the advantages of creating a tech pack in PLM, over a spreadsheet!

1. Central data location

When you build your tech pack in a PLM software, you can access it anywhere, anytime. Everything from your product information, measurement charts to sample iterations, revisions and approval logs are located on a centralized cloud-based platform.

You don’t need to pass around a file to collaborate with your team as everyone can access the file in real-time. Secure storage on the cloud means that you don’t ever have to worry about losing a file.2. No version confusion

When using excel sheets, every update leads to the creation of multiple versions of a tech pack. And then you have to email it back and forth for reviews and comments to send the updated file to your manufacturer. This makes it impossible to find which version is the latest one.

On the other hand, when you use a PLM system like WFX PLM, you can make edits directly on the platform and your supplier will see them immediately. This saves a lot of time and avoids confusion by keeping everything in one place. No more wondering if all departments are working off the latest version of a technical spec sheet with PLM.

3. Faster to create, easier to understand

With WFX PLM, there’s no need to search for new tech pack templates every time you need to create a new product. In PLM, there are varieties of tech pack templates to choose from. You can also create your own customized template.

Thanks to standardized modules, all product information is divided into pre-determined sections. This means that it’s not just faster to make a tech pack with PLM, it also helps you store all current and future product data in a standardized manner. This keeps your brand’s identity and brand standards consistent, which eventually makes it easier for manufacturing partners to understand your directions.

4. Improved communication

A Tech Pack created in PLM can be shared with anybody via email and can also be accessed at any time by anybody having access to it. You do not have to rely on any third party to send the email and then keep track of all the emails sent back and forth. You can also add comments on each module / section and have your discussion with other users on it.

PLMs make it easier to get an overview of each item, which can be filtered according to season, style number etc. This helps reduce delays, improves communication and keeps projects on track.

5. Better consolidation and tracking

Excel sheets do not allow you to group information into categories and show these categories as tabs. With tech packs in PLM, you can easily view all related information pertaining to a fabric, color, sketch etc. in one tab. This enables you to consolidate materials usage across product families and identify redundant materials, which can lead to cost savings.

You can go deeper and even add country of origin, supplier name as well as the purchase and selling price for each item within the tech pack for greater transparency into your production line. Overall, it’s much easier to track each style/product development process from concept to production in your PLM.

6. Save time with resource libraries

Adding measurements, color definition, product groups for every new product or variation can be a pretty hectic job to a tech pack in Excel. A huge advantage of using PLM for tech packs is having the ability to pre-feed libraries for materials, measurement templates, washing information, fits, color grading and more!

You can add your standard measurements for different products like one for coats, for jackets, for footwear and so on. So, when anyone wants to build a tech pack, all they have to do is pick the template from a dropdown menu!

7. Sample approval and management

As a designer, the biggest advantage of creating a tech pack in PLM is that it allows you to undertake the sample approval process for each stage of development. You can track first prototypes, pre-production samples and production samples from anywhere in the world with an internet connection.

The PLM makes it easier to effectively manage sample reviews, and integrate data from other systems and spreadsheets. This system also allows you to maintain a record of all samples created by all vendors over a certain period of time. The information on these samples can be accessed at all times by all people involved in the project.

What can you do with tech packs in WFX PLM?

We’re going to be honest: There are a lot of things you can do better with tech packs in WFX PLM. And that’s because tech packs are the cornerstone of the entire garment development process. They grease the wheels and keep the whole thing running smoothly.

For starters, tech pack templates in WFX PLM aren’t just static files—they’re responsive and dynamic, so they always load correctly no matter what device is being used to view them.

We automate most of your tech pack creation process. That means you’re not spending time manually entering all the data into a spreadsheet. It also makes sure that information is never lost or misplaced, which can happen when you’re working with a static file like an Excel sheet.

And then there are automatic updates and notifications, so you’ll know exactly when any changes have been made to your tech packs by anyone on your team. You have access to the entire version history of the tech pack, which is important because even small changes can have a big impact on the quality of the product.

That’s why we’ve also built features like approvals and messages for sample iterations into WFX PLM—to help make sure that everything is correct and approved before it gets sent off to the factory.

WFX PLM also has a library feature that allows you to save commonly used elements across tech packs so that you don’t have to re-create them from scratch each time. This feature helps make sure that your entire team is using the same format for tech packs (which also helps reduce errors).

You can choose your own layout, say for instance you don’t the picture on the right or you want to create two rows for the attributes – you can do all of that and more with WFX PLM.

Summary

In a nutshell, tech packs in PLM are more efficient and make it easier to share technical specifications with vendors and manufacturers. You can save time, improve communication, and reduce errors with tech packs in WFX PLM. Get a free demo to check it out for yourself!