How Cloud-Based PPC Tool Shapes the Future of Smart Factories?

Introduction

The manufacturing industry is going through a major transformation because of cloud technology adoption in smart factories. Using a cloud-based tool brings transformative changes to operation planning, production methods, strategic development, and manufacturing processes in smart factories.

A PPC tool (also known as a Production Planning and Control software) allows smart factories to access real-time actionable data to plan, monitor, and optimize their production workflows across the entire supply chain.

Let’s get a closer look and explore how cloud-based PPC tool helps smart factories streamline their planning and production operations more efficiently. Let’s get started!

Understanding the Role of a PPC Tool in Manufacturing

Production planning and control (PPC) operate in tandem to develop smooth and effective manufacturing processes. A PPC tool gives manufacturing businesses foresight into their production planning and helps fulfill client orders more smoothly.

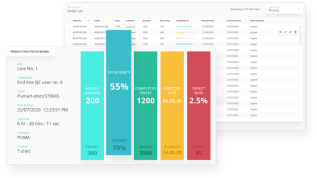

This tool is made to help businesses plan and control the smart factory’s production requirements with reduced waste of resources and idle time. During the production planning stage, the manufacturers determine what, when, and how much to make. They’ll have a visual playground ( charts, graphs, etc) where they can put all the data together and make more effective strategies to meet their manufacturing goals.

A production planning and control tool in manufacturing helps to:

- Create precise production schedules that support your business objectives.

- Streamline resource allocation to boost efficiency and cut costs.

- Monitor real-time production progress to resolve bottlenecks quickly.

- Gain valuable insights through detailed reports for smarter decision-making.

- Maximise cost per minute of the factory by clearly planned efficiency metrics

- Analyze performance metrics to drive ongoing operational improvements.

Why Traditional PPC is Not the Smart Way for Garment Manufacturers?

The traditional production planning and control (PPC) system comes with various limitations that negatively affect the overall efficiency of the garment manufacturing factories. Some of the major loopholes in using traditional production planning are:

- The traditional PPC system makes manufacturers struggle to respond to sudden market fluctuations, which create supply chain disruptions and equipment breakdowns.

- The traditional system has poor integration across departments, causing communication gaps and misalignment between production schedules and actual demand.

- Traditional PPC systems generate inaccurate planning of forecasts of future demand patterns, which lead to production problems such as overproduction and underproduction issues. If the production faces any obstacle, replanning garment manufacturing processes using traditional PPC is a painful task for the entire team.

- The manufacturers lack comprehensive supply chain visibility, which hinders their ability to track raw materials and finished products.

How does PPC Tool Transform Garment Manufacturing Processes?

A cloud-based production planning and control (PPC) tool helps businesses skyrocket their manufacturing operation efficiency. By using a reliable PPC tool, smart factories can access a unified system with real-time data to predict potential equipment failures, supply chain disruptions.

1. Demand Forecasting and Planning

By using the right ERP system, you would be able to store and create forecasts/bookings. With the right symphony, the planning system should allow you to visualize your capacity utilization under a forecast or booking.

2. Capacity Planning

The cloud structure of a PPC tool enables manufacturers to monitor available resources like labor, machinery, and raw materials in smart factories. The real-time overview of available resources allows manufacturers to perform adjustments by hiring workers and acquiring the necessary equipment and materials to satisfy forecasted requirements by flexing working hours.

3. Material Requirement Planning (MRP)

A PPC tool evaluates product schedules together with demand forecasts from smart factories to guarantee the proper timing of material orders. This MRP automation ensures efficient use of raw materials in order to minimize excess inventory and reduce storage costs.

4. Effective Manufacturing Scheduling

A Cloud-based PPC tool gives valuable insights into production lead times, available labor, and machine capacity to create an effective manufacturing schedule. It provides smart factories with clear visibility so they can make quick adjustments to accommodate any delays or changes.

5. Production Execution and Monitoring

The tool provides manufacturers with real-time visibility into production speed along with resource utilization and schedule adherence. Any delay detected by the system automatically generates alerts to manufacturers for prompt decision-making and to prevent operational inefficiencies.

6. Inventory Control and Management

The tool provides manufacturers with real-time visibility into the stock levels to optimize inventory. Thus, manufacturers can maintain optimal inventory levels in the smart factories and avoid disruptions in the production flow for improved efficiency.

7. Post-Production Analysis and Feedback

Cloud-based PPC tool provides insights into performance, efficiency, and resource usage post-production using detailed reports. The manufacturers can identify the areas that need improvement and improve the production planning efforts. Moreover, manufacturers can take feedback from various departments to drive more improvements in the processes.

How Cloud-Based PPC Help Garment Manufacturers Manage Ex-Factory Dates?

Managing ex-factory dates is a critical factor in determining production timelines and shipment forecasting in manufacturing. It serves as the backbone of efficient planning, ensuring that every stage of production aligns with delivery commitments.

With a smart PPC tool, manufacturers can effortlessly input order data into an intuitive interface, gaining a clear, real-time visualization of their production schedules across multiple clients.

For instance, if your current production capacity falls short of meeting demand on time, you have two options: scale up manufacturing or adjust deadlines strategically to maintain workflow efficiency and prevent bottlenecks. Aligning all processes with the Ex-Factory date is essential for on-time deliveries, optimal resource utilization, and buyer satisfaction.

Let’s Grow Together!

For smart factories, investing in a PPC manufacturing tool is a vital and wise decision to streamline operations, eliminate inefficiencies, and increase overall ROI. The PPC tool dramatically helps smart factories automate processes and align their production with customer demand. Moreover, the future holds significant potential for using mass production methods and process manufacturing methods alongside advanced technologies to enhance efficiency.

In the same way, advancements in PPC allow manufacturers to manage production quality while ensuring that their supply chain aligns with production capacities. This will help create smarter and more cost-effective manufacturing operations and help businesses reach their growth goals.

Shape the future of smart factories by leveraging the power of cloud-based PPC tool! Contact WFX to transform your manufacturing business and get access to the millions of possibilities that are awaiting you!