Tech Pack 101: Everything you need to know about fashion tech packs

Introduction

The tech pack is a cornerstone of the fashion design process. But where do you start? What essential information do you need? And what pitfalls should you avoid?

This guide will walk you through everything you need to know about creating and editing fashion tech packs.

What is a fashion tech pack?

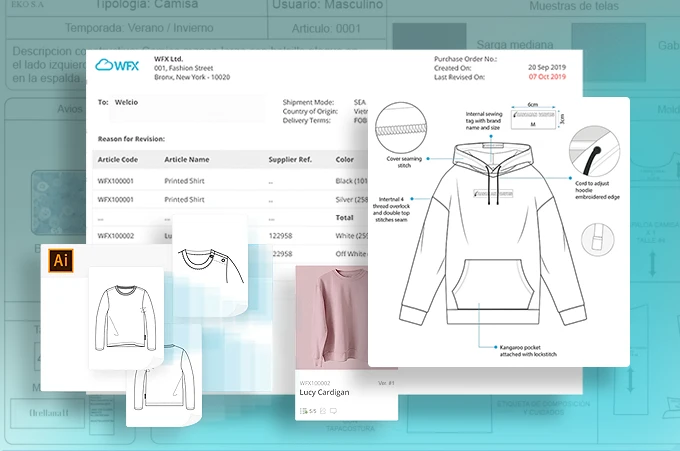

A fashion tech pack (or technical package) is a comprehensive document provided by brands or designers to factories. It details how to make, construct, and assemble garments or fashion products, acting as a blueprint to ensure proper garment production.

Typically used for large-scale production, tech packs include technical drawings, measurements, grading rules, colorways, bill of materials, construction details, costing sheets, and reference images. For smaller production lines, a spec sheet might suffice.

In short, a tech pack fashion contains all necessary information for efficient and accurate garment production at the factory level.

What Does a Fashion Tech Pack Include?

To the untrained eye, the contents of a tech pack can seem like an indecipherable collection of technical jargon. But if you know what you’re looking at and how to use it, it’s straightforward!

Here are the key components that should be included in your fashion tech pack:

- Product Summary: This should be brief but clear, mentioning the article name, code, short description, product type (e.g., jacket, shirt, top), color, gender, date of creation, last modification date, season, supplier/country of origin, and retail price.

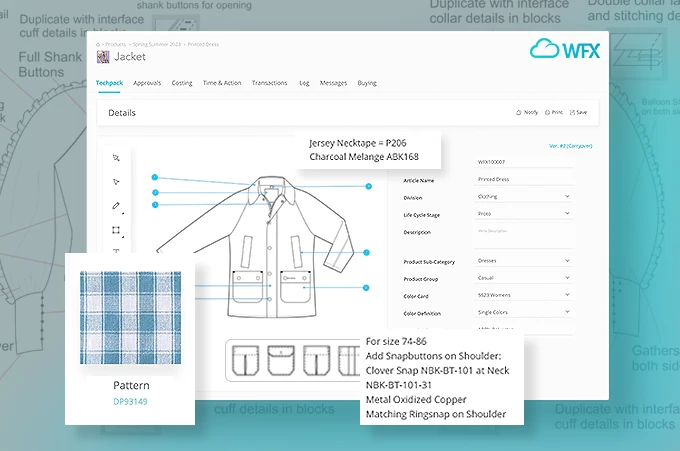

- Technical Flats: Also called technical drawings or fashion illustrations, they show how a garment would look when laid flat on a flat surface (hence the name). You must include technical sketches of how the products look from all angles—front, back, side and inside.

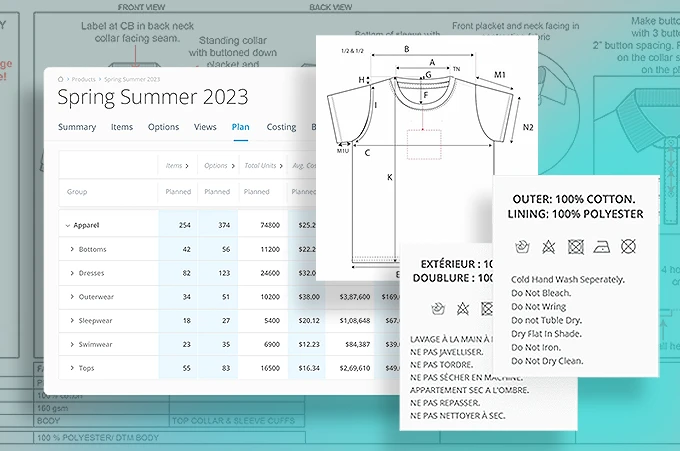

- Measurements/Grading Specs: Measurement sheet outlines all measurements across all sizes for each garment design to help ensure proper sizing later during production. It should also include tolerances for the respective sizes.

- Color Definition: This defines what colors the garment is available in. While colorways will show how these colors look when combined or with other fabrics or materials. You might want to provide a few different options here for your manufacturer to choose from.

- Bill of Materials (BoM): The BoM shows all the fabrics and trims that go into a particular piece. You could also include information about hardware for zippers and buttons under this heading as well. This document is particularly important as it’s referenced by both parties for costing purposes as well.

- Construction Details: construction details will tell the manufacturing team how each part of the garment should be put together—from stitch types on seams to placement of pockets to closures like buttons and zippers.

- Care Information: This outlines how end customers can clean/maintain each garment once they purchase it, so apparel products stay in good shape over time. These instructions may not necessarily need to come from you—you can always ask your manufacturer what they would recommend here instead.

- Cost Sheet: A garment cost sheet is a detailed list of the costs associated with designing, manufacturing and shipping a garment. It includes the costs of fabric, trims, and labor (with respective quantities) for each garment.

- Comments & Feedback: This is where the product development team can review the sample and add comments/feedback for any changes they expect from the manufacturer. This will help them make sure they’re on track with your vision for the product.

How to Make a Fashion Tech Pack: Step-by-Step Guide

Creating a fashion tech pack can seem daunting but breaking it down into steps simplifies the process. Here’s a step-by-step guide to help you create an effective tech pack.

- Create a Table of Contents: Reference a template or build a checklist based on your factory’s requirements.

- Gather Technical Specifications: Include flat sketches from all angles, measurements, colors, and materials used.

- Start with Measurements and Drawings: Outline your garment idea with precise measurements and detailed drawings.

- Detail Materials and Production Methods: Specify how to cut fabrics, create interfacing, etc.

- Add Technical Information: Provide specific techniques, such as sewing facings or attaching buttons.

- Include Additional Notes: Add style edits or special requests regarding quality requirements.

Use these steps to develop a tech pack that effectively communicates your design vision to manufacturers.

Why Do You Need a Fashion Tech Pack?

The importance of tech packs for standardizing production, ensuring quality control, and maintaining brand consistency cannot be overstated. Here are the key benefits of tech packs in fashion:

- Reduce Miscommunication: A tech pack example can serve as a universal language, bridging gaps between designers, manufacturers, and suppliers. This ensures everyone is on the same page, significantly reducing errors and misunderstandings.

- Environmental Benefits: By specifying exact material requirements and production methods, tech packs minimize waste and promote sustainable practices. They help avoid excess inventory and unnecessary material usage.

- Quality Control: Comparing samples against the detailed specifications in a tech pack ensures that the final product meets the desired standards. This rigorous checking process highlights any discrepancies early, preventing costly mistakes.

- Production Tracking: Tech packs enable comprehensive tracking of each production stage. This detailed oversight ensures that no steps are missed, timelines are adhered to, and any potential issues are identified and addressed promptly.

- Shipping Efficiency: Detailed packing instructions included in tech packs help protect products during transit. This ensures that items arrive in perfect condition, reducing returns and increasing customer satisfaction.

- Vendor Selection: Tech packs facilitate the process of sourcing and selecting manufacturers. By providing detailed specifications, brands can obtain accurate quotes from multiple vendors, making it easier to compare costs, negotiate terms, and select the best partner for production.

- Collaborative Environment: Tech packs foster collaboration by centralizing inputs from various departments and stakeholders. Digital communication tools, such as Adobe Illustrator and Computer-Aided Design (CAD) software, streamline the sharing and updating of tech pack information, enhancing teamwork and efficiency.

Tips for Annotating Images in Tech Packs

When creating a clothing tech pack for a new style, it’s crucial to remember that factories may not interpret images as expected. Here are some tips and best practices to ensure clarity:

- Label Everything: Explicitly label components, such as button placements, to avoid misinterpretation. For example, without labels, buttons might be sewn 0.5 inches apart instead of the intended 1 inch.

- Color Accuracy: Be mindful that colors can look different on screens. Specify exact color codes to avoid discrepancies.

- Detailed Instructions: Provide comprehensive written instructions with every image to ensure nothing gets lost in translation.

- Use Arrows and Callouts: Highlight specific areas of the image with arrows and callouts to draw attention to important details.

- Include Multiple Views: Show different angles and perspectives of the garment to give a complete understanding.

- Standardize Symbols and Terminology: Use consistent symbols and terms throughout the tech pack to avoid confusion.

Difference Between Spec Sheet & Tech Pack

While the terms are sometimes used interchangeably, spec sheets and tech packs serve distinct purposes.

Spec Sheet:

- Purpose: Provides detailed technical information about a product.

- Contents: Includes product codes, descriptions, measurements, technical sketches, materials, trims, and colors.

- Format: Generally flat documents without extensive visual elements like mockups.

- Use: Suitable for straightforward product descriptions and smaller production runs.

Tech Pack:

- Purpose: A comprehensive document that guides the entire production process.

- Contents: Contains everything in a spec sheet plus grading sheets, order forms, garment spec sheets, fabric requirement charts, bill of materials, construction methods, pattern sketches, and renderings or mockups.

- Length: Could go up to 10-20 pages or more, with extensive details and visual information.

- Use: Essential for large-scale production, ensuring accuracy, consistency, and effective communication with manufacturers.

In summary, tech packs provide a more in-depth and detailed guide for producing a complete product line, while spec sheets focus on specific technical details.

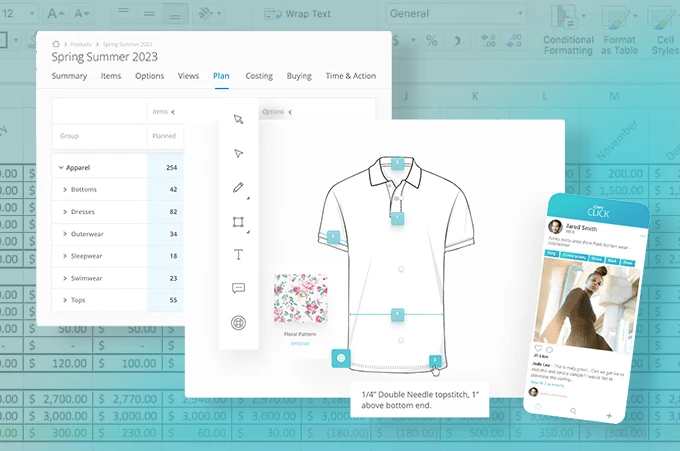

Excel vs. PLM for Fashion Tech Packs

Creating fashion tech packs can be challenging, but the right tools can make a significant difference. Here’s a comparison of using Excel vs. PLM for fashion tech packs:

Microsoft Excel:

- Manual Entry: Requires manual input, which can be time-consuming and error prone.

- Cost-Effective: Low initial cost as most businesses already have access to Excel.

- Flexibility: Allows customization based on specific needs without predefined templates.

- Limited Collaboration: Real-time updates and collaboration are challenging.

- Organization Challenges: Difficult to manage visual and detailed information effectively.

PLM Software (such as WFX PLM):

- Streamlined Process: Centralizes all essential information, making tech pack creation efficient.

- Real-Time Collaboration: Facilitates instant communication and feedback within the same platform.

- Mobile Accessibility: Vendors can access specs on the production floor through mobile apps.

- Error Reduction: Automated processes reduce manual errors and ensure consistency.

- Higher Initial Cost: Investment in software can be higher, but it often pays off with efficiency gains.

- Standardization: Ensures all apparel tech packs follow a consistent format, which can be beneficial for quality control.

Choosing the right tool will depend on your project complexity and budget. For simple projects, Excel might suffice, but for larger, more complex productions, PLM software offers significant advantages. If your team is distributed or involves multiple stakeholders, PLM’s collaboration features are invaluable.

How to Make Tech Packs Faster

Creating a tech pack can be time-consuming, especially for more complex garments. For example, where a simple t-shirt tech pack could take a designer 1-2 hours to make, it may take the same designer 5-6 hours to create the tech pack for a jacket with elaborate detailing.

However, there are several strategies can help speed up the process:

- Organize Files: Keep all original sketches and references in one labeled folder or a centralized product lifecycle management system. This streamlines the process and reduces time spent searching for materials.

- Standardize Communication: Work with manufacturers familiar with your processes to minimize back-and-forth communication.

- Improve Design Process: Ensure sketches and designs are detailed and accurate from the start to avoid rework.

- Leverage Technology: Use modern tech pack software instead of outdated spreadsheets. These tools are designed for visual information and can significantly reduce the time needed to create tech packs.

Conclusion

Fashion tech packs are crucial for developing new products and communicating with manufacturers, but they don’t have to be difficult to create.

Use existing templates to save time and focus on filling them out correctly rather than starting from scratch. Avoid outdated spreadsheets when better solutions exist. Embrace technology to streamline the process and ensure accuracy.

The fashion industry constantly evolves, and leveraging modern tools is essential to stay ahead. Use technology to save time and resources while improving your work quality.